Efficient manufacture of first-in-class antimicrobial

Customer challenge

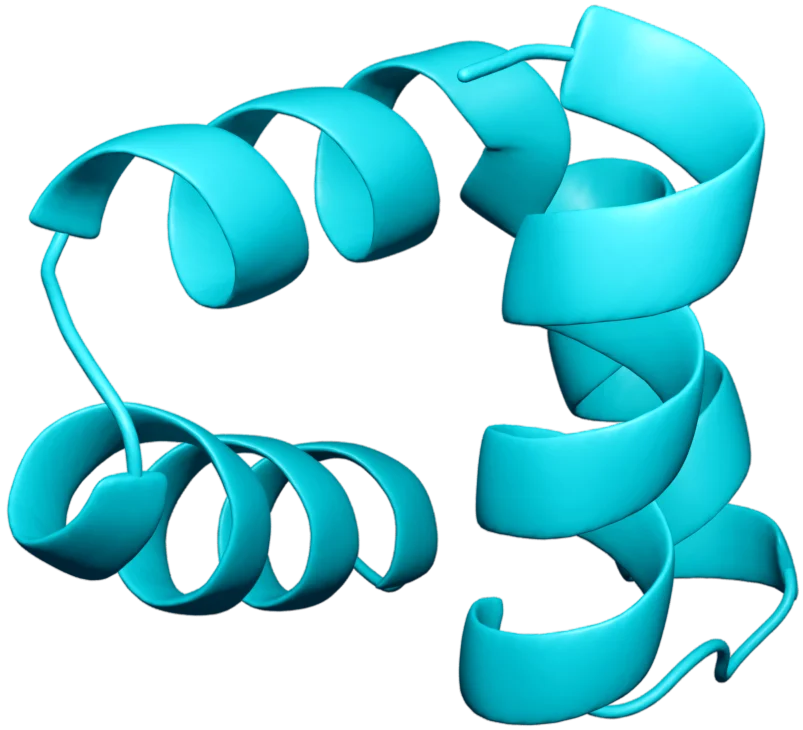

Unable to progress a promising, first-in-class 51-amino acid antimicrobial peptide, due to its high potency resulting in very low yield from recombinant bacterial production.

We’ve moved (just around the corner) to our own brand new, state-of-the-art facility - so please update your address book with our new details in the footer below.